Why Record? Infrared Video

Stockton Infrared Thermographic Services, Inc.

Abstract

The days of the hand written infrared report are over. With the speed, portability, availability and relatively inexpensive costs of today’s infrared imagers, computers and image processing systems, the infrared thermographer can collect, process and produce professional inspection reports with greater ease than just a few years ago. Due to the lawsuit-rich environment in which we live, documentation has become a necessity instead of a luxury. An infrared video is a well-documented survey and an important way that the infrared thermographer can protect himself and produce a quality report. The small amount of additional time (cost) associated with recording and data logging can easily be justified. This paper discusses the reasoning behind full-time recording, the advantages, as well as the practical applications and associated costs with this method of data collection.

Introduction

There is a tremendous amount of information that is produced from the process of aiming an infrared imager at an object. We cannot possibly remember all of it. What happens in the case of most infrared thermography is that the thermographer – in a very few seconds – sees the image, makes a judgment and decides whether or not to ignore, record or save the image that is on the screen at that moment. Herein lies the problem. If the infrared thermographer could see into the future and know that he or she would never need this information again, it would be fine not to document it. Unfortunately, it is impossible to know whether or not the information will be needed in the future. This paper could have been entitled ‘WHY DATA LOG’, since it is absolutely necessary to create a data log (a list of all items recorded referencing a time seen or encoded on the videotape). Recording imagery forces one to log the data and infrared videos can be rewatched as many times as necessary.

Advantages

A) Database Creation

The most important advantage of recording and producing infrared videos is the creation of a database. This can be invaluable in some cases, to prove or disprove that a change has occurred in the imaged object. In many cases, trending is the only means by which the thermographer can tell if an object or system has a problem, or is developing a problem. With image processing systems that are available today, analysis by trending is possible. Of course, one has to record the images to be able to see a thermal phase change.

B) Increase in Thermographer Accountability

Any infrared thermography quality assurance program should include regular reviews of the field thermographer’s videotapes. By reviewing the infrared videos, the following questions will be readily answered:

- Are the proper imager settings being used?

- Is the thermographer taking the proper amount of time to do the job?

- What criteria are being used to determine a thermal anomaly?

- Did the thermographer inspect everything on the list?

- Are proper data collection and safety procedures being followed?

- Is the quality of the images sufficient for the purposes of the survey?

C) Improved Inspection Quality

What is the measure of quality of an infrared survey? Certainly pretty colors are not. Was everything inspected? Were all the problems found? Were the objectives achieved? The answers to these questions lie in documentation techniques, reporting format and accountability of all involved. It is very unlikely that a thermographer that records and data logs is going to do an incomplete job, particularly when everything being inspected is documented.

Let’s look at the example of an infrared survey of electrical switchgear. An incomplete survey would be characterized by not checking items, checking items that are not under normal load conditions, not removing the covers, or not knowing the difference between normal conditions and problems. If the thermographer data logs and records everything that he inspects, it is going to be harder for him to do an incomplete or incompetent job and get away with it. It will be obvious to anyone reading the data log and reviewing the tape, that, for instance, the covers were not removed or the project not properly completed. Without this type of documentation, all the recipient of an infrared report of a survey that was not recorded has to judge the quality of the survey, is the word of the thermographer that all the items (other than those made as findings) – were “OK”. Infrared Videos allow for a second set of eyes to ensure the quality of the inspection.

D) Reduction in Thermographer’s Liability

Reducing liability is a major factor in many companies’ decisions to perform infrared testing. The liability has not magically disappeared, it has been transferred to you – the thermographer. We accept a certain risk by doing an infrared survey for hire. However, a reduction in the infrared thermographer’s risks will occur if all items are well documented. When complete infrared survey documentation including an accurate data log is created, there is a meeting of the minds between the thermographer and the end user as to what is to be, what needs to be and/or what has been surveyed. If a piece of equipment is locked-out or not operating, it needs to be brought to the attention of the end user so that it can be inspected later. Also, upon reviewing the data log, he may discover that some important items are not on the list. Any legal department will advise you to get it in writing. Nobody can ignore a documented problem, even though there may be a tendency not to react quickly.

This is a good place to interject the following anecdote:

I was surveying a large paper mill when I came upon an extremely hot (150C degree delta-T) piece of main switchgear. I immediately informed the electrician I was working with, and showed him real-time what the problem was. I told him that it would be advisable to get the supervisor of the line and show him what was going on, so that they could plan a shutdown. I continued surveying (at another location) since there was nothing I could do right then. About 15 minutes later, the electrician returned alone.

He said that the supervisor would come by “sometime this afternoon”. I went to three people before I got to the man who could make a decision. I told this fellow what I had found to which he replied “Son, I’m making $50,000.00 an hour from the #10 Paper Machine I don’t care if that switchgear blows into the next county!!!” Since I had the problem on the infrared videotape, on the data log and I had made a sufficient fuss, I felt if something happened, I was covered.

As it turns out, the boiler for #10 was scheduled to have the grates replaced within 10 days. The plant manager was gambling that the switchgear would make it to the shutdown. The point is, since I was not making $50K per hour from the #10 line, I was not willing to gamble by not making a real effort to inform the decision-maker of my finding.

The Nuts & Bolts of Recording

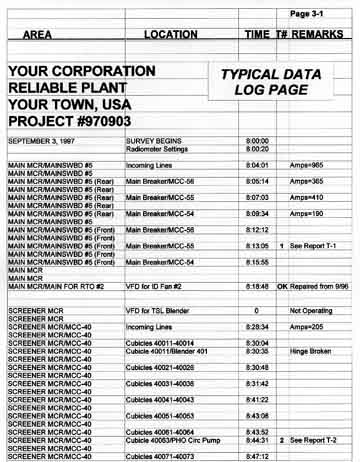

It would seem that the process of recording infrared images is as simple as turning on the camera and pushing the record button. This is the case. Recording – in and of itself – takes very little time. However what is time-consuming, is creating a data log the first time. THIS MUST BE DONE ACCURATELY AND METHODICALLY. An accurate data log creates a road map through whatever you are surveying. This is often the most cost-effective path. In order to make any sense of an infrared videotape, you have to have some way of referencing the object to a space on the tape (See an example data log Figure 1). I know what you are thinking… I’ll just go from say, top to bottom, left to right that will save time data logging each individual item. Sorry, that does not work.

Here’s a scenario from the pages of ‘a day in the life’ of a full-time recording, electrical & mechanical infrared thermographer

You are in the #7 Motor Control Room standing in front of MCC 12R. You are going to record the MCC cubicles starting with the incoming lines compartment, then down vertically, then to the next section, and so on. You will save time by logging the time at the beginning only, because you will be able to find anything you want on the infrared video later by counting the cubicles. You start recording. On cubicle C4 you find a problem. A discussion breaks out between the electrician accompanying you and his compadre as to the merits of installing the proper size overloads in a motor starter. Just at that moment, in walks the chief electrical supervisor, and his mechanical counterpart in the plant. They want to see that coupling on the #3 Condenser Water Pump that you found earlier. Owing to the fact that you are working for these fellows – you stop what you are doing and everyone convenes at the coupling. Sure enough there is a problem that the mechanical supervisor asks you to record for him, again. You do so, everyone leaves and back to the MCC you go. Now where were we…C4, C5, C6 or D1??? The moral of this story is to log each individual piece of equipment record in a methodical manner.

Some consideration must be taken as to what format, etc. of videotape to choose. I use 8mm because the tapes and the recorder are compact, and of sufficient format quality for my purposes. When I complete a survey, I record a VHS copy of my 8mm to give to my clients. I want them to have the tape in their possession and review it, and if I ever lose the 8mm, they have a copy. The videotape manufacturers all tell you to store the tapes on end. Jobs are labeled by date and thermographer code. I also print readable labels for each (See Figure 2).

THE ECONOMICS OF RECORDING

Let’s look at the costs associated with infrared video and documentation. The increased costs of recording video is not in the materials or equipment, but in the training and implementation of the program. There is never a time when not recording is better than recording. How many infrared thermographers reading these words, wish that they now had a piece of video on something that they shot in the past?

There are many reasons given for not recording. Here are a few:

“It takes longer to complete a job” True. But only about 25-30% longer to record on the first survey, because you have to create a data log, and it has to be right. It takes about 15% longer on the second and following surveys, since you will have the data log saved (or printed) for the next time. You may even save time by not having to figure out what to survey, since you have a road map. Also, you will not miss anything from last survey because it’s notation is on the saved data log. When you are finished, your end user will have a COMPLETE and ACCURATE record of what was surveyed. What takes time is being sure what you are recording.

“Since it took longer, it cost more.” That’s right. The importance of a quality infrared survey far outweighs the slight increase in cost. By the way – are you being paid by the hour, by the day, by the job, or by the number of items fast-scanned per hour.

“My clients and I don’t have the budget to do a thorough job.” Agreed! His or her budget has been spent to pay for downtime created when the machine that someone forgot to scan failed, because no one had it on the list.

“There aren’t any labels on the equipment, so how can I data log them?” Correct. You are actually going to have to track them down, find out what they are, and verify what you are looking at. If you ask three different people in a plant what an unlabeled piece of equipment is, you will get three different answers. Next year, even if it is still not labeled, you will know what to call it. Also, the act of trying to label the equipment may even prompt the company to correctly label their equipment. This will be a benefit to everyone.

“I might see something I don’t understand, so I don’t want to record it and later have it used against me.” Affirmative. Even the most well meaning, conscientious and competent thermographers make mistakes. Take heart, you’ll be in good company, and you might learn something. Isn’t that what IR/INFO is all about? Full documentation will insure that the thermographer will not let something slide.

“The end user doesn’t want or need all this data.” Wrong. He may not want it-but he does need it! He may say he doesn’t need it, but he will sleep better knowing that the job was done right.

Analog vs. Digital

Digital is the way of the future. However, analog is not a dirty word, particularly as it pertains to the use of analog videotape to record continuous imagery of adequate quality for historical record keeping purposes. It is cost effective and compact, particularly 8mm tapes. If space (on the cart) were not an issue, we would use the Super VHS format. During report preparation, we take IR and visual images from the videotape with video capture hardware and software and ‘paste’ the photographs and thermographs first to the clipboard, then onto the report page. This allows us to crop and/or move the images around, look at the page and see if it gets the point across. We always print a back page with images of different imager settings, angles, photos of ammeter readings, etc., which we think will help the user understand what we are trying to show. Often this makes for a total of six images for a single finding. Post-processing results in a picture of adequate-to-good quality, even when compared to present state-of-the-art all digital reports.

Now the issue of memory. One two-hour videotape can hold the approximate equivalent of over 120 gigabytes of information based on a video rate of 60 fields per second (30 frames per second) and a single-field .tif image capture of 300kb. Even a 60kb .jpg image capture scenario equates to over 25gb of information on a single videotape. Try storing that on a 3.5-inch floppy diskette or a 10 or 20mb flash card. Diskettes and camera on-board flash memory cards are for saving those wonderful digital images of obvious thermal exceptions that are going to end up on the report later in the day. Videotape is: back-up for all those images if and when your computer crashes for storing all of the other images, such as panning in a 20′ x 10′ electrical panel, three-story high steam boiler or large building for storing of all the things you looked at that appeared to have nothing wrong with them. Next week or month, when that item with no previous discernible or unusual thermal infrared signature decides to malfunction in a spectacular and world-class way, you’ll have it on video as the ‘cool cucumber’ that it was when you performed the survey. Score one for the conscientious thermographer.

At present, we do not see the widespread use of digital video recording devices in the field. Soon, for a few thousand dollars, one will be able to record digitally, that is pixel by pixel, frame by frame, field by field, without loss. Until then, we will have to settle for analog outputs of 525-line NTSC TV signals, recorded onto standard videotape capable of 330 lines of information. Although the full measure of videotape-recorded information from our modern imagers is somewhat distorted and degraded, it will continue to have tremendous value as a back up to computer failures and for historical records keeping. Most image analysis software will allow accurate 8-bit post-processing from videotape-recorded imagery if no temperature parameters were exceeded during recording. Inframetrics and other manufacturers offer IR cameras with the capability of saving 12-bit imagery (on flash cards), which allow for full dynamic range post-processing.

The Down Side of Recording

As stated earlier, we do accept a certain amount of risk by performing an infrared survey for hire. We decrease the liability by recording a videotape so that we can – in effect – hand over the liability to the end user, by providing him with proof-positive (in the form of complete documentation), that the objects which we surveyed were in more or less the shape that we say that they were in. Therefore we have to accept that by providing excellent documentation we could be handing the rope to the hangman.

The answer to this problem is proper training, continuing education and to have a set of specifications that are agreed upon at the onset, and that these specifications will be followed. We all have to ignore minor problems-at least what our experience has taught us are minor. But these minor problems could come back to haunt us legally. It is going to be hard to prove the negative, when in fact, the positive has occurred, to spite our IR experiences.

If you do an excellent job, the reduction in liability that comes from recording, exceeds the increase in liability that comes as a result of recording.

In Conclusion

As the infrared industry continues to develop, documentation will become more important and required. Infrared video recording and data logging creates a database, making the thermographer and the end user accountable for all items surveyed, thereby reducing the liability and improving the quality for both the end user and infrared thermographer.

Related Articles

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera