School Without Walls e-Learning

Ron LaBrie, Senior Consultant, HumEng International Inc

As time goes by – New technology requires new training ideas so a mill can make that new technology work properly.

ATLANTA, Dec. 31, 2008 (Viewpoint) – A long time ago, it was decided that training on the job in the pulp and paper industry consisted of following Joe around.

That was when pulp and papermaking technology was simple and slow-changing. It was the time when employees learned what they could or were permitted to learn. It was a time when mills were running at full capacity and people had the luxury to learn by trial and error.

Nobody really cared that what was learned was a fraction of the knowledge of the previous generations. It did not occur to anyone that the mind is a faculty that forgets, that bad practices are passed on as well as good practices, that information not written down and only passed on verbally degrades, degenerates and is subject to the same principles of entropy that pumps are. And nobody ever expected the changes of the past 10 to 15 years, although we were so much fascinated with the future…with the future of technology, not with the future of knowledge requirements for the people that would have to make that technology work.

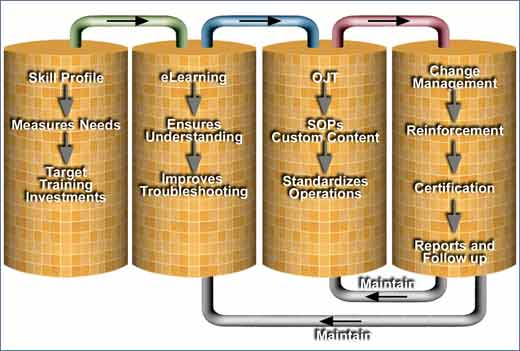

Figure 1 – Connecting the training element silos

Then, the bubble burst, as it always does when too many expectations are placed in one dimension of a multi-faceted industry. So what to do, where to start, how to proceed with increasing the skills and knowledge of our manpower? So many unanswered questions are an indication that we have lost touch with the problem. It must be big, it must be expensive and it must hurt to implement the solution.

The School Without Walls (SWW) is a supplier-driven venture to help the industry increase the skills and knowledge of its manpower. The School Without Walls Pushes the Envelope (P&P, April 2008) article concentrated on the eLearning aspect. This article is devoted to on-the-job-training (OJT).

On-the-job training (OJT) is one of the most costly types of training a mill can do. It is a critical event used to pass on the “how to” of the job incumbent. It is the period of time required for a person in a new job to learn the job from the “elders”. It is a ceremony that is loaded with consequences. Despite its cost and importance, OJT is not done in the structured, organized and documented fashion that leads to increased productivity and safety. The following are some benchmarks that can be used to evaluate OJT.

Job analysis: When training workers to do a job, the training content has to be meaningful, organized and oriented. This is only achieved if the content is job-based through a job Skill Profile.

The job Skill Profile identifies important job functions and documents the knowledge and skills required to successfully perform those functions. The Skill Profile is best developed cooperatively, by an “exemplar” (the best at the job) and a training analyst. It is an analysis of the job that begins with interviewing an “exemplar” to identify and document the job’s “doing skills”.

The “doing skills” are listed under major skill sets such as: Operate equipment; verify/measure; troubleshoot; communicate; safety, etc.

The “doing skills” are validated by others holding the same job as well as by supervisors. Once the “doing skills” are identified, the “knowledge skills” are added. “Doing skills” are how the job is done. “Knowing skills” are “why”, or what must be understood. A job Skill Profile can contain 10 to 50 skills.

Most “knowing skills” can be learned through self-study (eLearning) and can be delivered and tracked on-line by the School Without Walls. Most “doing skills” have to be learned on the job, reinforcing the need for a carefully planned and implemented OJT program.

SOPs/SMPs: A Standard Operating Procedure/Standard Maintenance Procedure is a step-by-step description of the tasks of a “doing skill”. Again, the “exemplar”, the person that is known on the worksite to be the best at that skill, is interviewed. Each step is further described using visual support to render the task understandable and learnable. The draft SOP/SMP is validated by others doing the same task and by the supervisor.

All SOPs/SMPs are linked to a specific “doing skill” on the Skill Profile. The Skill Profile becomes the training road map. The SOPs/SMPs become the “to be framed” materials. The implicit knowledge of exemplars becomes explicit and can be transferred to anyone required to do the tasks.

Select in-house trainers: “Doing skills”, documentation written in learnable SOPs/SMPs format and “knowing skills. available through eLearning, have to be transferred through a coach, a senior operator/maintenance person on site. It is imperative that trainer selection be based on criteria that reflect the values of the mill, the credibility and empathy of the training function. In-house trainers cannot be appointed to the job. They must volunteer. They must satisfy selection criteria and be trained.

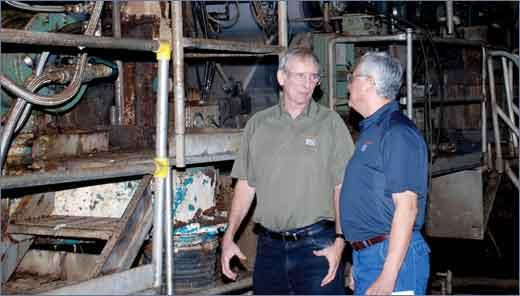

Michel Gratton and Leo Garcia discussing wet end SOP content

Training the trainer: Training is a non-disruptive means of effecting change on the work site. It is a critical function and the incumbents have to be properly prepared. A Train-the-Trainer workshop is not designed to produce professional trainers, but instead to confer confidence to volunteer employees wishing to help others learn the tricks of the trade. The soft skills associated with the craft of a trainer are important in helping change the way a job is done.

The traditional Train-the-Trainer curriculum focused on classroom technique and group learning. ELearning and OJT require Train-the-Trainer programs that focus on one-on-one coaching, mentoring and evaluating.

Link with quality systems: SOPs/SMPs production based on the “exemplar” is very closely related to the quality system, and it is important for the SOPs/SMPs production effort that they do not require a parallel effort to manage, but are fundamentally interlocked. The authors have never seen a quality system that could not adapt to and integrate SOPs/SMPs. Although the primary role of SOPs/SMPs is not quality system oriented but training/learning targeted, it is possible to adapt the quality system to this effort.

This ensures two things. First, it prevents duplication of effort; secondly, it helps keep the training content alive. The SOPs/SMPs are incorporated in the Skill Profile (job description) of a position. The trainer and trainee continuously review these during the OJT.

Communication: We seem to forget that change is a matter of knowing why to change, knowing what to change to, having the possibility to change and last, but not least, having it reinforced. Training is a process that needs to be explained, to be repeated and to be followed up. It is like exercising: too much too quick and too condensed, makes sore muscles. Instead, communication has to be continuous, in small doses and sustained.

All the steps of the OJT and eLearning processes have to be communicated and de-mystified and, if we consider training as a lever of change, they also need to be enforced through structured, punctual and continuous communication, support and evaluation.

Evaluation: The objective of OJT is to have incumbent workers put in practice the best practices of “exemplars”. This does not happen by chance. It happens within a training process that is based on a training infrastructure. Both the best practice documented through SOPs/SMPs and the application of that best practice have to be evaluated. The first process is linked to site-specific quality systems and the application of the best practice is linked to the shop floor supervisor.

The Skill Profile or training road map comes in very handy. The Skill Profile is the checklist or report card. The SOPs/SMPs are the content.

Both the trainer and the supervisor have to contribute to these evaluations. The trainer evaluates whether the incumbent employee has learned and understood the skill. The supervisor evaluates if the incumbent worker has put the learned SOP/SMP into practice.

The interaction of the trainer, incumbent worker, and supervisor is critical to ensure standardization between various persons doing the same job.

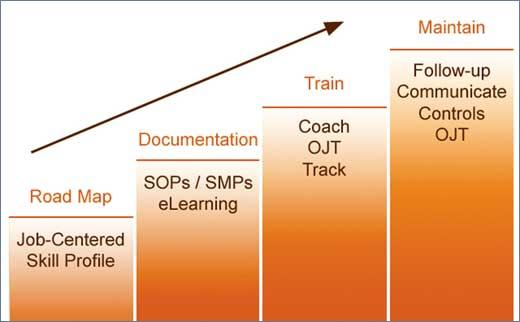

Figure 2 – Training infrastructure steps for benchmarking

Summary

• A job Skill Profile is a training road map

• eLearning is economical for “knowing skills”

• Structured OJT is required for “doing skills”

• SOP/SMPs are developed for training on best practices

• Training the Trainer is focused on coaching and mentoring

• Evaluation consists of seeing if in fact the investments are meeting objectives.

The effects of employees knowing what to do (SOPs/SMPs), why they are doing those tasks (eLearning) are many. The standardization between employees doing the same job increases, problem-solving and troubleshooting capacity increases, and productivity and safety follow.

How does your OJT compare to these benchmarks? How can it be compared? How well do you manage your most important training instrument? And, how well do you pass on your best practices?