Reducing Stores Cost and Lead Times through a Joint Supplier Venture

Wayne Bru, Smurfit-Stone

I shall start with an overview of why this program was instituted; I will then give a brief description of how the process works. Next, I will touch on the methods employed by the integrator and mill personnel to affect the cost savings. I will then present the results obtained and finally discuss some of the problems encountered during the implementation. My presentation today will describe the implementation of an integrated supply initiative in the Smurfit-Stone Container Corporation mill in Brewton, Alabama.

The division initiated this program. A team was formed to decide if integrated supply was a viable alternative for our division; once the decision was made, a selection process was begun to select the integrator and beta-test site mill by September 1998. GISO (Grainger Integrated Supply Operations) was selected as the integrator and the Brewton Mill got the job as the guinea pig.

To be honest, the mill was less than enthusiastic about being involved with integrated supply. There were rumors flying that GISO would take over the storeroom operation completely and our employees would be laid off. We had just completed the implementation of a CMMS and were still working out the bugs with that system. The fact that Brewton had the CMMS installed contributed to our selection.

The initial scope of the implementation was that SSCC Purchasing would purchase all bulk chemicals, raw materials, capital items and contracted labor. GISO would purchase all MRO items, both catalog and non-catalog. Catalog items are those assigned a catalog ID number. These are items that will be purchased more that once. These include stocked items which are items that an on-hand quantity is maintained with specified maximum and minimum quantities; non-stocked items which are items assigned a catalog ID but a quantity is not maintained on the shelf (these include expensive items that we should have time to order and items that are needed to repair assemblies such as pump rotating assemblies or gear reducers); direct charge items which are items that are ordered upon request but are not issued individually such as oil, conduit, structured steel and pipe; and consigned items such as fasteners and tubing fittings, which are free issue items. The storeroom would continue to be staffed and managed by SSCC personnel. One of the main reasons for this decision on the operation of the storeroom was that at the Brewton mill the issue clerks help the mechanics determine what parts they want. If the clerk was given a catalog ID of the part that was needed and all he had to do was retrieve it, an outside group could manage and staff the storeroom. But that is not the case at Brewton.

GISO’s first time on site was early July of 1999. Conversion began in August. Conversion consisted of GISO assigning a SAP number, a vendor and a price to each of our catalog IDs.

The go-live date was December 15th with approximately 5500 of the 33,000 catalog items converted to the GISO database. The plan had been to convert all but OEM items to the GISO database prior to going live but, as has been my experience with data conversion, it did not go as well as anticipated. The remaining items had to be converted as they were requisitioned by the PASSPORT system.

At start-up, the GISO team consisted of a site manager, assistant manager, three buyers and a material analyst. The material analyst managed the consigned items and the warranty program and assisted the mill in identifying surplus and obsolete items.

The mill implementation team consisted of the Mechanical Maintenance Superintendent, the Purchasing Agent, the Maintenance Planning Superintendent, the Storeroom Supervisor and the Accounts Payable Supervisor. During the implementation, this group met with the GISO Site Manager and Assistant Manager weekly. Now, two years after implementation, we meet once a month.

The mill had installed a new CMMS-Indus International’s PASSPORT in April 1999. GISO uses SAP software. The requisitions for both catalog and non-catalog items are created in PASSPORT. Purchase orders are created in PASSPORT by GISO personnel for the items GISO purchases and through EDI a purchase order is created in SAP. GISO personnel then only have to release the Purchase Order. The SAP Purchase order is the order that is sent to the customer.

Items are received in the PASSPORT System by SSCC Storeroom personnel and then, through EDI, they are received in the SAP system. Receipt in the PASSPORT System updates the on-hand quantity of catalog IDs and adjusts the average unit price.

Prior to integrated supply, the invoicing was done manually on an item by item basis. Now all items purchased by GISO are invoiced electronically.

Cost reduction is achieved through parts purchasing, inventory management, warranty, process savings and special projects.

GISO achieves lower prices through contracts with our vendors. Several major contracts were renegotiated early on and GISO was able to get better pricing than corporate in some instances. If GISO was not able to get better pricing, we then used the corporate agreement giving us the best of both worlds.

When GISO renegotiated the power transmission contract, we actually changed vendors. The mill was concerned about the service level from the low bidder. The contract included a 40-hour a week service representative. An employee from outside the supplier’s local branch filled that position. He is in the mill 40 hours a week as promised and has a desk in the Maintenance Planning offices. Since we have only two maintenance planners, he has been a big help with the procurement of non-catalog items. This has allowed the planners to spend more time in the field looking at the jobs to be planned.

Grainger also reduced the number of suppliers. When GISO arrived at the mill we had 984 active vendors and today GISO only uses 313. Fewer vendors increase the amount of business with individual vendors and results in savings through volume and rebates with several of the vendors with whom we have established contracts.

Fewer vendors give us the ability to control the actions of the vendors. A supplier doing $250,000 of business a year is more apt to respond to our request than one doing $10,000. For example, since there is a PASSPORT (mill) Purchase Order and a SAP (GISO) Purchase order for each purchase, it can be confusing for the vendor since the packing slip must reference the PASSPORT Purchase Order for Storeroom personnel to receive the order in the PASSPORT system.

There were a few suppliers that either could not or would not reference the correct Purchase Order. GISO solved the problem by changing suppliers. They are much more hard-nosed with our suppliers than our mill personnel would be.

Another method of price reduction is the substitution of lower priced items. When GISO put our data for cataloged items into their database, they did so using our specified manufacturer and part number. They were free to buy from any vendor unless our description specified or prohibited a certain vendor. If GISO discovers a substitute, they do not buy the substitute unless the mill personnel agree to the change. The mill personnel who have to agree to this are maintenance and production who will be affected, not stores or purchasing. This has helped to integrate the GISO personnel into the daily mill operations. The buyers deal directly with the personnel requesting the material not just with purchasing and stores. They get out in the mill and interact with mill employees much more than our mill purchasing group.

GISO negotiated with our frequent suppliers to eliminate freight cost except for the expedited items requiring airfreight or hotshot. There are 17 suppliers who charge no freight for normal delivery, etc. Of course, these expedited costs can be greatly reduced with increased maintenance planning giving stores and GISO more time to procure what is needed.

Another reduction is the increased use of consigned free-issue items. The main effect of consigned items is the reduction in inventory but costs are reduced because free issue items decrease issues, requisitions, purchase orders and receipts.

Free issue items are all vendor managed. These items include nuts and bolts, small pipe fittings, valves, small electrical accessory items, and commonly used pipe gaskets. These items are not issued or included in our cycle count program. Since these are owned by the vendor until consumed, they do not add to the value of the inventory. Once every week or every other week the supplier checks the bin levels and restocks to maintain the maximum bin levels as specified by the mill. These items are then shipped as a lot. So instead of a 50-200 line purchase order a week per supplier we have a one line purchase order. The Grainger Material Analyst manages this program. If we change vendors or add and substitute items to the consigned inventory, he takes care of everything but assigning a catalog ID to the new item which is done by stores.

Another area of savings that we have not utilized properly is warranty repair on items such as electric motors and repaired hydraulic cylinders and pumps. The Grainger Material Analyst manages this program. This is done outside our CMMS. The storeroom informs him when an item is issued. He surveys the dock where the maintenance crew returns repairable items and checks the items to insure they outlasted the warranty. Lead times have decreased significantly through swifter processing of the requisition by GISO personnel and better response by the vendors prompted by the GISO buyers. The PASSPORT system creates a requisition for a catalog item as soon as the on-hand quantity reaches the order point as a result of an issue, reservation, or cycle count. Normally 60% of these requisitions are converted to purchase orders by 5PM. There were 325 outstanding requisitions when GISO assumed the purchasing function. The graph shows the outstanding requisitions at the end of the month for the year 2000.

Processing the requisitions quickly is only one part of reducing lead times. Expediting to ensure the suppliers meet the promised delivery dates is another important part of the process. Each purchase order line is assigned a promised delivery date in the PASSPORT and SAP systems. The GISO buyers regularly check on the items that are nearing the due date. This system works quite well.

We track stock outs and one of the categories we track are stock-outs due to delivery. In other words, there is an item requested that is not available and the item is past due. Since the implementation of integrated supply, this category of stock out has decreased by 24 percent. The on time delivery has increased considerably as seen by the graph.

In April of 2001, GISO has moved to 4 other mills in the division: Fernandina Beach and Jacksonville in Florida and Hopewell and West Point in Virginia. Several changes have occurred as a result of this expansion. A purchasing group has been established at our division headquarters in Jacksonville. These buyers process all of the fast turning items that have established prices with a specified vendor. Although these are processed by buyers not onsite, they are purchased from the same vendors as if they were processed on site.

With the creation of the team at division, we have decreased the on site group from 6 to 4 which includes a site manager, two buyers and a material analyst. If there is a problem with the delivery or an item delivered is incorrect, mill personnel contact onsite personnel regardless of who had processed the purchase order.

At present, we are processing the purchase orders manually but the PASSPORT system has the ability to produce “blanket” purchase orders. This process creates the purchase order directly when a catalog item’s on-hand quantity reaches the reorder point. This will, of course, cut down on the processing time. But in our mill processing can become too quick. Several times a day items are returned. Depending on the quantity returned and the cost of the item, we may decide to cancel the purchase order. This then adds work to a process we are attempting to streamline. The items selected to be processed automatically to a purchase order must be inexpensive and fast turning so that ordering them before the order point is reached does not greatly increase the inventory value.

Another advantage of developing a divisional team is that we are able to transfer items between mills. If one mill requisitions an item that has been identified as surplus at another mill, GISO will arrange a transfer between the mills instead of purchasing the item.

Of the five mills using GISO as the integrator, three use the PASSPORT system (the plan is for all mills in the division to eventually convert to PASSPORT) and the other two use separate systems. Although the division is creating a “corporate” catalog for the PASSPORT system, at present it would be difficult for the buyers to determine if one mill’s surplus item is indeed the same as the item being requisitioned. Since GISO assigns a SAP number to all items stocked and non-stocked that are purchased, we have a common numbering system that aids this initiative.

Several mills were shutdown when Smurfit and Stone merged. The storerooms in these mills are being cataloged and assigned SAP numbers so this inventory can be utilized.

So what has this effort accomplished? For the year 2000 the Brewton mill realized a cost savings amounting to 15.4% of the total purchases by GISO. The breakdown of the savings were:

So what has this effort accomplished? For the year 2000 the Brewton mill realized a cost savings amounting to 15.4% of the total purchases by GISO. The breakdown of the savings were:

| Actual | Percent of Annual Forecast | |

| Parts Purchasing | 58% | 152% |

| Inventory | 26% | |

| Warranty | 1% | 25% |

| Process Cost | 6% | 92% |

| Project | 9% | 36% |

In 2000, inventory decreased by 2.6 percent. Of course, this was less than the division team expected. But in the 9 years prior to the implementation of integrated supply, inventory increased by 39% or approximately 4% a year. In the same time frame Annual Restocking Cost had increased by 31%.

Some of the assumptions made by the implementation team concerning inventory were flawed. They assumed there were many duplicated cataloged items, a large percentage of items that were obsolete and that many of the original OEM parts were still being purchased from the OEM. Many of the duplicates and obsolete items were eliminated in the mid 80’s when the first CMMS system was installed. As equipment was replaced, the planning group identified the obsolete parts and stores removed them from the inventory.

The problems encountered were establishing the electronic interfaces, educating the vendors to the changes that were required of them and overcoming the negative attitude of mill personnel. Although it was a struggle that lingered on for about 9 months, the interfaces are now working properly. This was accomplished through many hours spent by GISO and SSCC’s IT personnel on the mill and corporate levels. I am not familiar with the details of the EDI set-up because that occurs mostly in the purchasing and account payable functions and because I am just a computer-illiterate user.

It took several months for the vendors to get comfortable with the fact that orders were coming from GISO and not SSCC. Many outside sales reps panicked before they realized they had not actually lost the mill business. Another problem as mentioned earlier was referencing the PASSPORT Purchase order on the packing slip. The progress is shown on the graph of Supplier Compliance. The ones we have problems with now are the vendors with whom we place only a few orders a year.

The attitude of the mill personnel has improved in most areas. I was at best neutral towards integration at the beginning. GISO’s customers in the mill – maintenance and production personnel – are very pleased. The response by the GISO team is excellent. The word is if you do not want it, do not order it because it will be here before you can change your mind. There are still a few die-hard hourly personnel in the storeroom who are always wanting to blame GISO if something goes wrong, but even they are complaining less.

The biggest pocket of resistance remains in purchasing. This is understandable since this is the function most affected by GISO’s presence in the mill. There are still some discussions, shall we say, over who is to buy certain items.

All in all, we feel the implementation of integrated supply at Brewton has been successful. The GISO team is easy to work with and there has been significant savings. The fact that GISO has expanded to four other mills indicates that division management agrees.

Related Articles

Keys for Effective Troubleshooting

Analyzing Semiconductor Failure

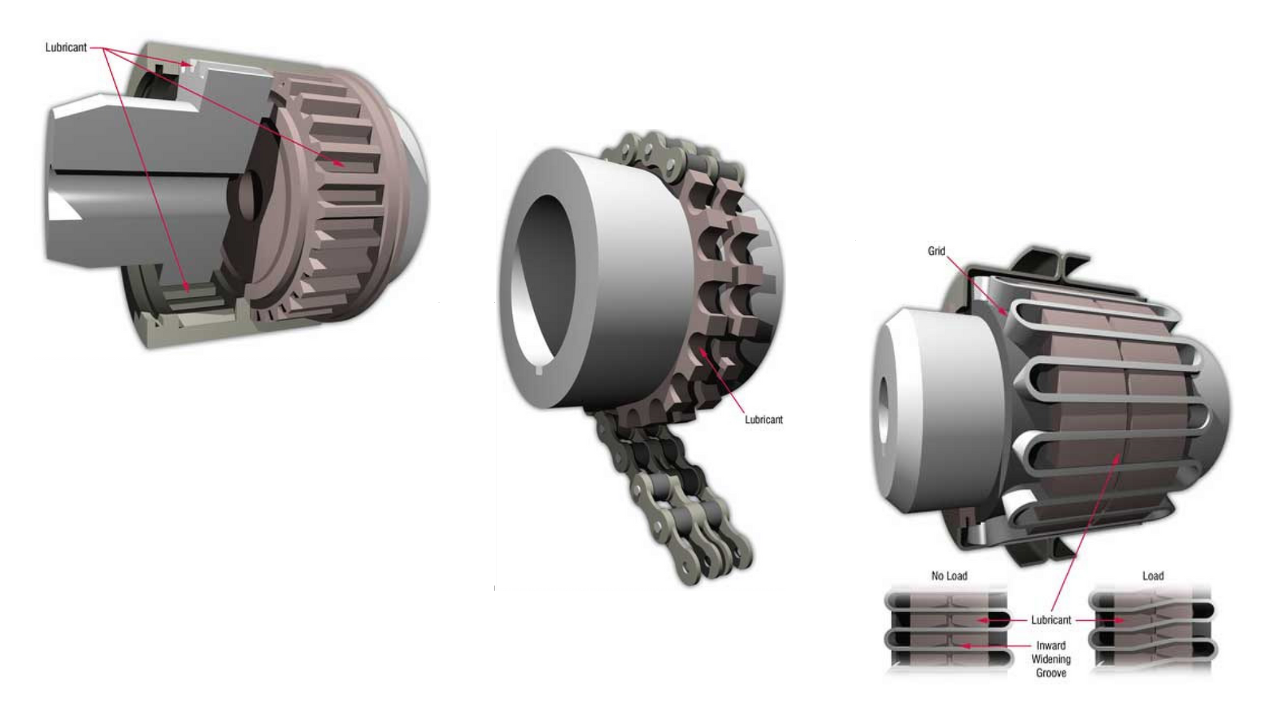

The Lubrication Requirements of Couplings

What is the True Downtime Cost (TDC)?

Improvement: What Comes First?

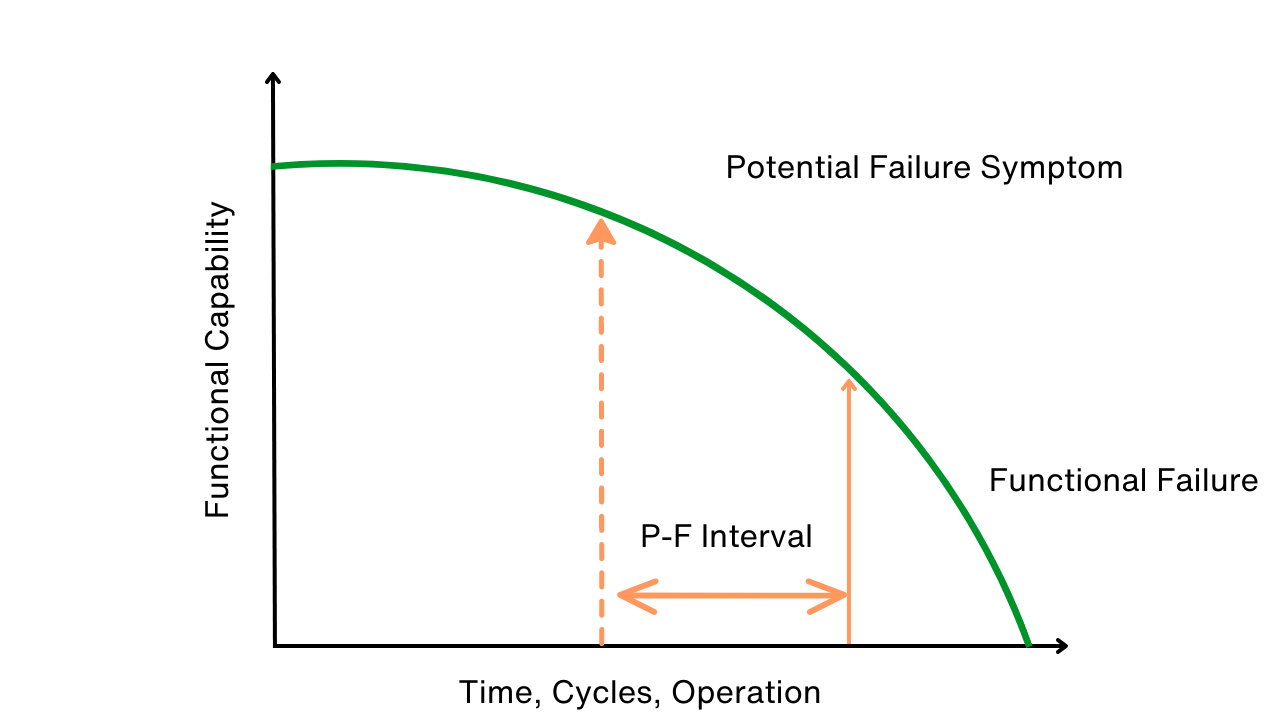

Use P-F Intervals to Map, Avert Failures