Double the Drive Life at One-Third of the Cost

Peter Wright, Drives Products Service Manager, ABB Drives

Many drive systems go to an early grave after only about 10 years of operation. Reconditioning an existing drive system could enable it to operate reliably for another decade and can be achieved for just 30-40% of the cost of a new drive system. Peter Wright, Drives Products Service Manager for ABB in the UK explains how.

Not so long ago, a variable speed drive was considered a piece of solid state electronics that, once installed, could be left to itself. In many places, maintenance teams still overlook the drives and hope for the best, but downtime and costly repairs can be the consequence, if older drives do not get proper attention.

“ABB was among the first companies to recognise that drives require service. In the early 1990s, we were already issuing maintenance schedules for drives,” says Wright. “But still, 60 percent of our field activities and 85 percent of our workshop requests are reactive repairs. This means that significant attention and money is spent on costly plant recovery following unplanned downtime.” According to Wright, the normal life expectancy of a drive is 15-20 years. In that time certain maintenance activities are required to ensure that a long and trouble-free service life is achieved. Every drive comes with a maintenance schedule that outlines the manufacturer’s recommendations. This includes routine maintenance, for instance annual air filter replacement and fan renewal every three or six years dependent upon the fan type. Such maintenance activities can be easily carried out by the in-house maintenance team or with the assistance of a local engineering firm and will increase your drive life.

Components Aging

But after about 10 years, some of the electronic components begin to reach the end of their lives. The ageing of the components will begin to have an impact on the reliability of the drive. In particular, the electrolyte in the capacitors dries up. This affects the performance of the gate driver boards, which provide energy storage for switching. This can cause pulses of different shape and size compared to when the drive was new. “At this stage, we recommend reconditioning of the drive,” says Wright. “We normally schedule reconditioning to take place in the ninth service year, to ensure it happens before any problems are experienced. But if the drive is used in a high ambient temperature, this may be needed sooner.”

Poor Connections

As well as capacitors, potential problem sources include corrosion of ribbon cable, or worn-out gold plating on sockets where cables are frequently plugged in and unplugged, with poor connections as a result. Optocouplers also deteriorate with time. These are devices that use a short optical transmission to transfer a signal while keeping elements electrically isolated. The output of these devices reduces over time and the signal gets weaker. As a consequence of a lack of maintenance, false trips may result. Changes in switching pattern will be experienced as a reduction in the performance of the drive. In the worst case, the power stage might fail, which usually means an expensive repair bill. During reconditioning, the power boards themselves are not replaced, but the components that impact on them are. Failure to replace these components in time may result in a costly power device failure. A reconditioning service should include visual inspection, cleaning, a thorough faultfinding analysis, preventive maintenance according to the schedule, repair if needed and functional testing. Reconditioning an existing drive achieves more than just maintained reliability. It helps retain the expertise of the staff that has learned to work with a particular piece of equipment. It also retains the value of the spares stock which, if the drive is renewed, will become redundant.

Reduced Lifecycle Cost

Reconditioning is a very effective way to reduce the life cycle cost of high power drives, but for drives of 50 kW or lower, replacement tends to be a better option. Reconditioning should be considered for drives in excess of 100 to 150 kW.

Reconditioning practice varies between industries. In the water industry, reliability is important, as loss of water supply can be costly and reconditioning is easy to carry out here. Pumping stations almost always have duty, assist and standby pump sets, so one drive can be taken out of service without any problems and taken back to the workshop for reconditioning. However, the area where drive reconditioning takes place most frequently is in the process industries, in sectors such as cement, metals, sugar and paper. Here, the maintenance teams are acutely aware of the fact that downtime costs money. For instance, a paper machine can have 30 to 50 drive sections and if one of these goes down, the whole machine stops. Maintenance is regarded as a profit centre and a way to prevent failure. In this light, downtime becomes the cost of inadequate maintenance. Success, to these maintenance teams, is 100% availability, not a quick and effective repair job.

Equipment Availability a Priority

PT Riau Andalan Kertas (RAK) in Indonesia is the world’s largest pulp mill, producing 2 million tonnes of pulp per year and 350,000 tonnes of uncoated fine paper. It is an advanced paper mill and equipment availability plays a key role in the company’s operating strategy. Maintenance schedules and preventive maintenance kits are keys to sustaining availability of the company’s No 1 Paper Machine. This has an ABB drive system comprising 49 drive sections, commissioned in 1997. During the first five years, operation was excellent, but then the drive maintenance team noticed a slight decline in availability. To restore and sustain the original high availability, RAK and ABB teamed together and made a site survey to analyse the situation. Based on the survey results it was concluded that all the maintenance according to the maintenance schedule had to be performed. Up to this point, RAK had been conducting maintenance according to its own maintenance plan. However, the maintenance schedules based on the latest experience were not available at the early years of operation of Machine 1. As a result of the new maintenance regime, availability has improved significantly.

Drive Plans for Life

Another example is Borealis, a leading provider of plastics solutions. The production site in Porvoo, Southern Finland, manufactures petrochemical products and polyolefin plastics. It has a capacity to produce approximately 2 million tons per year. The plant has used ABB drives for several decades and ABB has a preventive maintenance contract for all of them. The objective is to maintain high drive reliability and minimise lifecycle costs, as well as to guarantee rapid spare part and repair work deliveries. The contract also contributes to the best use of plant maintenance resources and availability of service engineers. Borealis uses scheduled production shutdowns to carry out drive maintenance. Most production lines have at least one weeklong scheduled maintenance shutdown each year and the annual maintenance work on the drives is carried out during these production shutdowns according to schedule. In addition to planned maintenance, ABB’s lifecycle plans for drives help define the time when a drive should be reconditioned or replaced.

Maintenance Policies Vary

“Policies on drive maintenance and reconditioning vary a great deal between companies,” says Wright. “Some are proactive, others just install their drives and hope for the best. Some get away with this, others don’t. But particularly those that have drives operating in hot environments should be aware that component aging is an issue that needs to be dealt with seriously and that solutions are available. After reconditioning, the drive should perform as good as new again – we even give a full one-year warranty on the whole reconditioned drive, not just the replaced parts.” Drives under 400 kW can be returned to the workshop and reconditioned. The controlled conditions at the workshop help ensure that the service job is as effective as possible. However, removing the drive from the site is not always feasible. Reconditioning then has to take place on site and ABB has developed methods for effective decontamination.

Related Articles

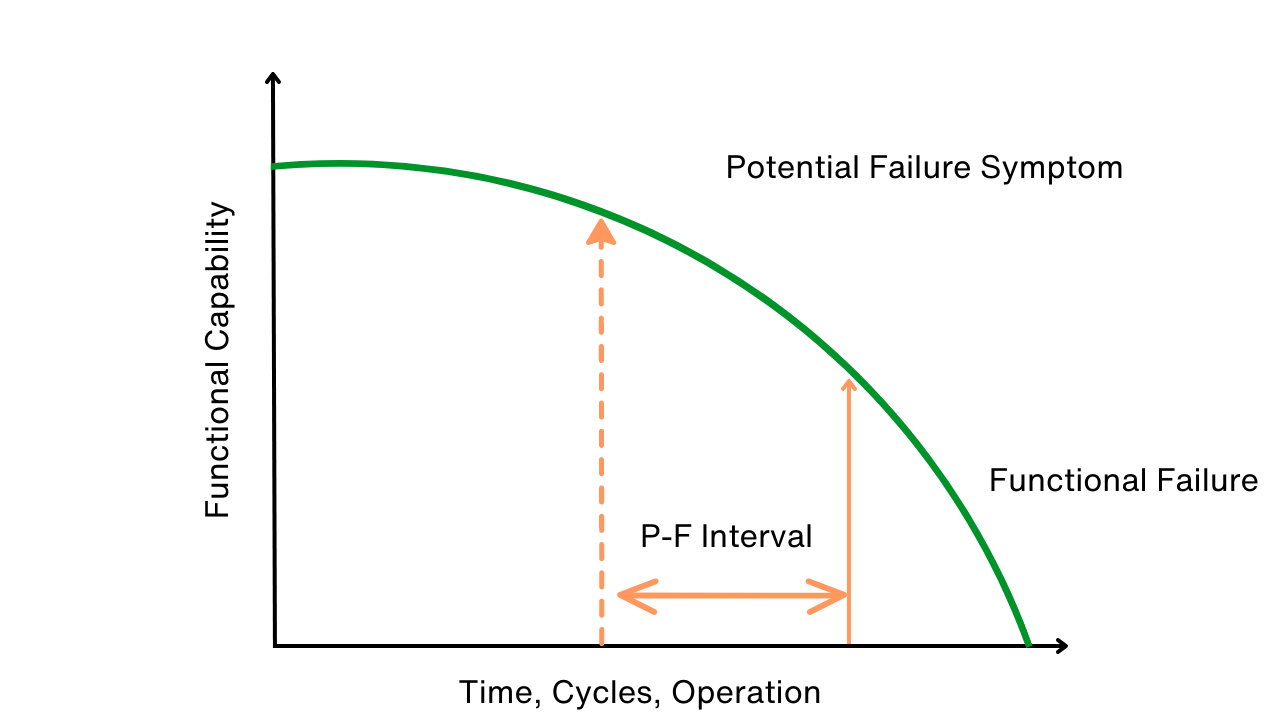

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability