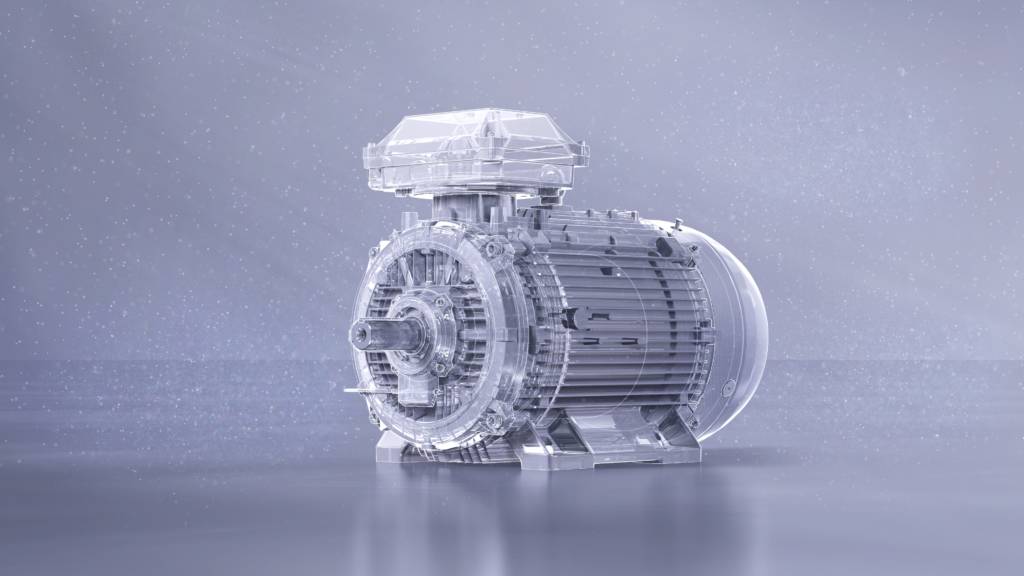

High-efficiency SynRM motors, a game changer in potentially explosive environments

Safety is critical in this industry, especially for applications in potentially explosive environments. Introducing the new IE5 SynRM Increased Safety motors represents a game changer, giving chemical manufacturers access to the most energy-efficient motor and drive technology. The new motors offer up to 40 percent lower energy losses than commonly used IE3 motors while meeting stringent safety standards.